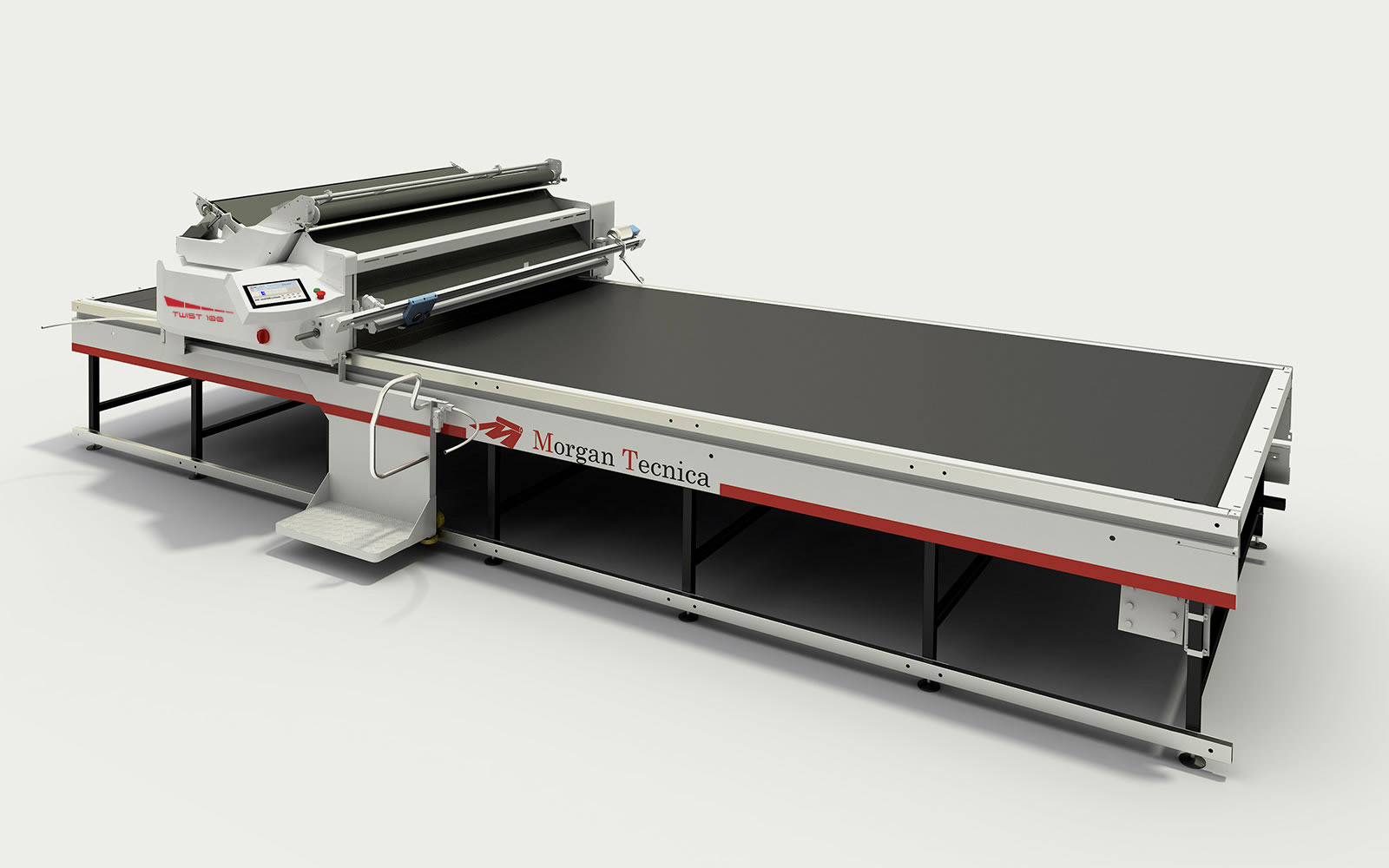

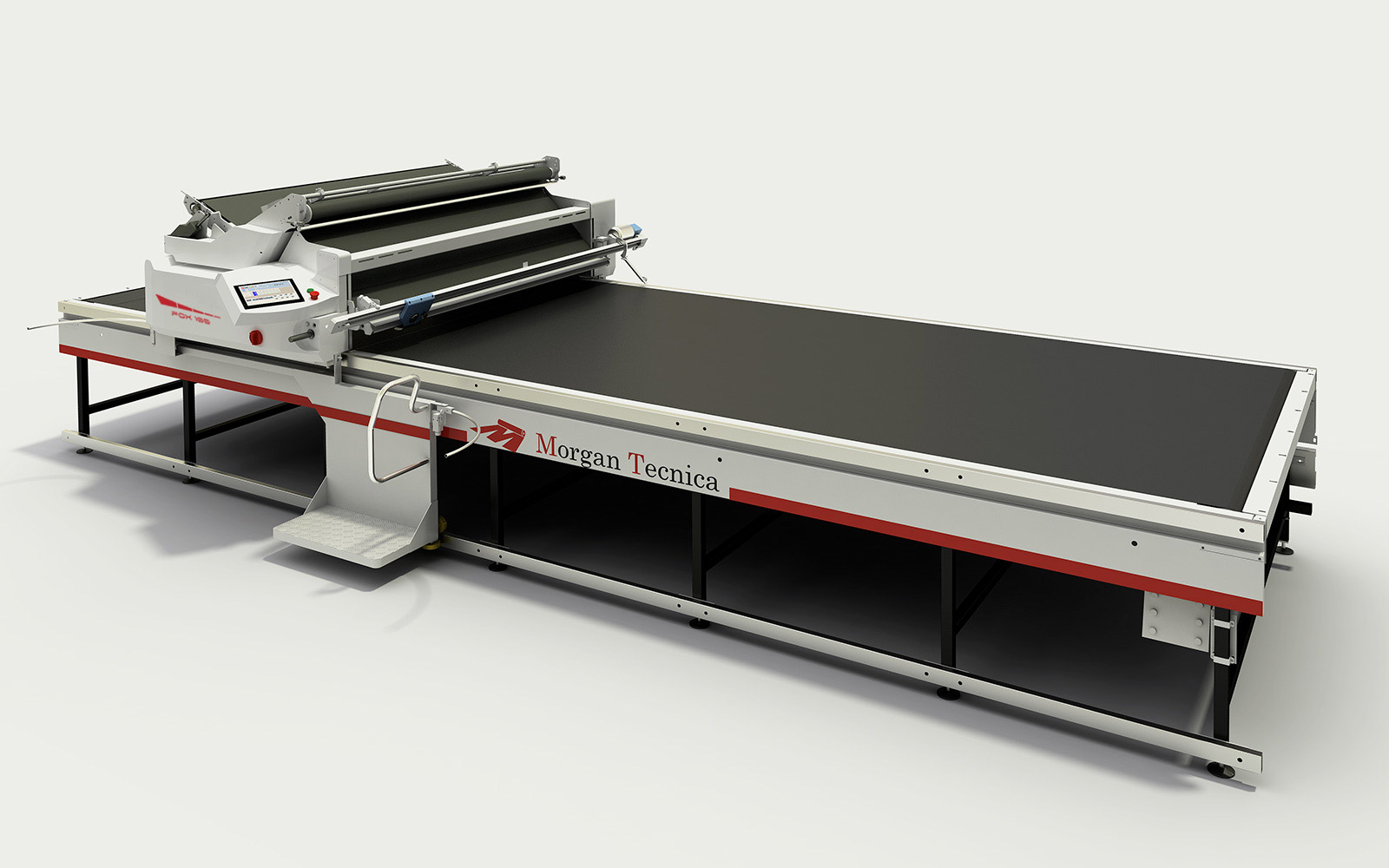

FOX

100

Highest level of technology and performance

Robust and versatile, while still remaining compact and agile. It is the ideal solution for continuous production of regular lays, even with different types of fabrics, because of it's ability to set up and manage several spreading

profiles in the on-board computer.

Every detail has been carefully designed to make the operator feel comfortable. The design is modern and ergonomic. The machine is easy to use, utilizing an interactive computer touch

with Windows OS and a software developed ad hoc. The cradle turret uses a single, solid PVC belt (not parallel stripes) which guarantees perfect and even grip throughout the fabric width. It utilizes an electronically controlled

“dancer bar” and encoder for “tension free” spreading without end-catchers.

All movements are electronically and digitally controlled, with possible multi-function setup, so that every user can actually create and store

different profiles, which can be customized for individual needs and material types. The PC Touch with Windows OS and Wifi connection allow remote updates and support service.

TECHNICAL SPECIFICATIONS:

Max speed: 100 m/min.

Width available: 180 – 230 cm

Max capacity: 100 Kg

Max roll diameter: 50 cm

Voltage: 400V 3Ph 50/60 Hz