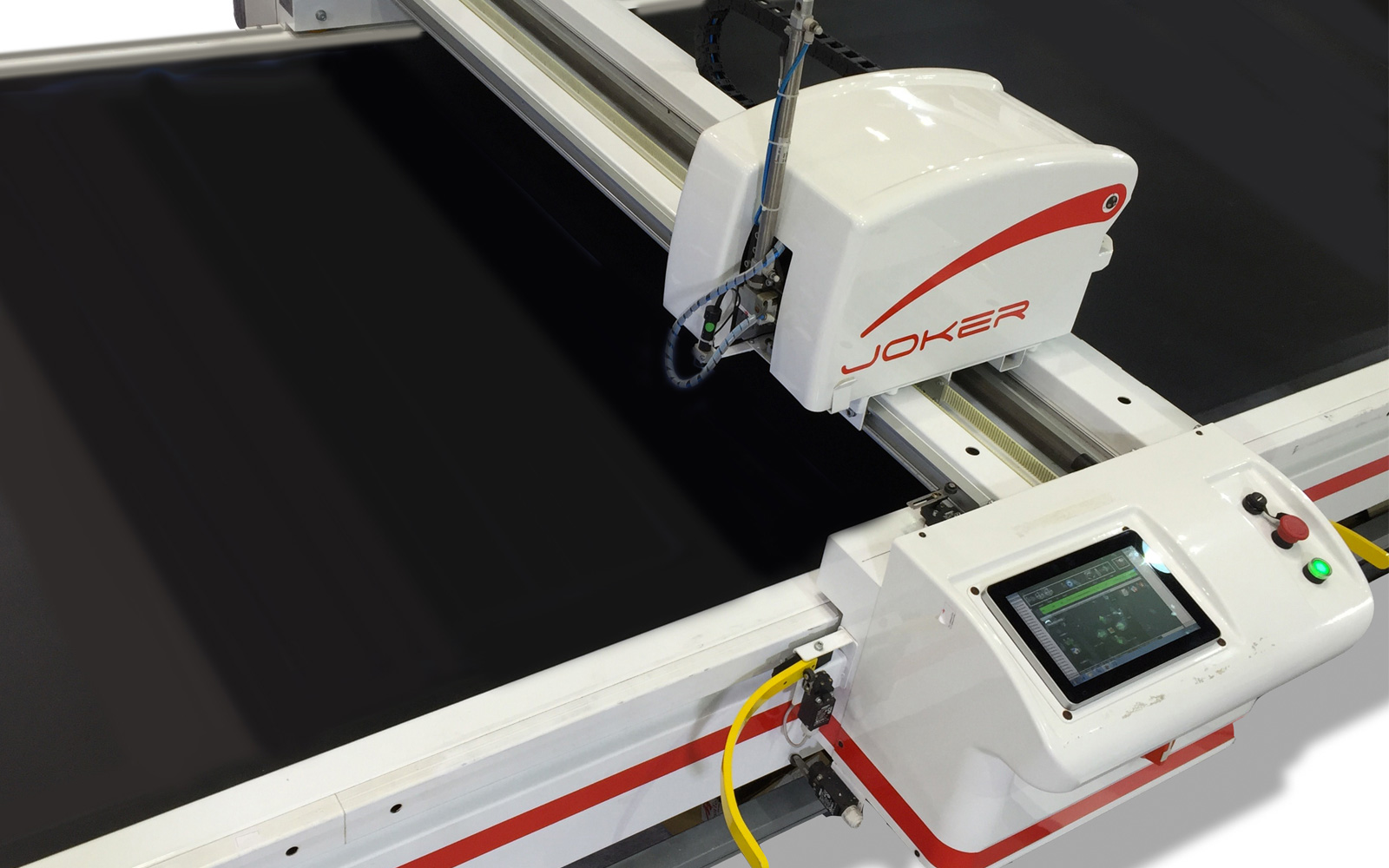

Joker

386

Automatic, fast, economic and eco-friendly

Designed with maximum compatibility in mind for any spreading lines. It guarantees fast identification of cut pieces, and a high reduction of time and paper wastage. The labeling is done fully automatically and independently from spreading

and cutting, optimizing the dead times between these 2 working operations. It is able to interface with existing Cad systems, via wireless technology and uses standard file formats HPGL, HPGL” and ISO.

Label stickers,

of customizable dimensions, are printed by thermal printer and placed at the center of each piece, in order to aid in the easy and fast piece identification. It maintains the option to print on multiple rows, using different fonts,

including bar code. It has a High Ecologic Profile system, which minimizes paper usage and it does not require ink cartridges, which eliminates the need for a special disposal procedure.

TECHNICAL SPECIFICATIONS:

Lay Thickness: 10-20 mm

Max Speed: 15m/min

Usable Fabric Width: 180/230cm